Unlock In-Depth Knowledge on Travertine and Its Essential Sealers

Exploring Travertine: A Distinctive Natural Stone for Your Home

Travertine is an exceptional natural stone that forms through the mineral deposits left behind by hot springs. Renowned for its porous nature and stunning range of earth-toned hues, travertine is a popular choice for flooring and wall cladding in various residential and commercial properties across the United Kingdom. Its aesthetic charm, coupled with remarkable durability, makes travertine a versatile option for both indoor and outdoor spaces, enhancing the overall ambiance of any environment.

The presence of travertine is evident in many iconic structures and contemporary homes throughout the UK. From the breathtaking Roman baths in Bath to the quaint rustic pathways of countryside cottages, travertine imbues a sense of timeless elegance that homeowners admire. However, the natural beauty of travertine can diminish over time without appropriate maintenance. This highlights the critical role of sealants, which are essential for preserving the stone’s allure.

A sealer acts as a protective shield against stains, spills, and moisture, ensuring that the natural beauty of travertine endures. Over time, sealers can deteriorate, necessitating their removal to maintain the stone's visual appeal. Understanding the safest way to strip old sealers off travertine is crucial for keeping surfaces immaculate and highlighting the stone’s inherent beauty without unsightly blemishes or damage.

Professional Suggestions: Recommended Products for Everyday Travertine Maintenance

Fila Pro Floor Cleaner

|

Lithofin Easy Care

|

Vileda H2PrO Spin Mop System

|

Exploring the Different Types of Sealers Utilised for Travertine

Sealers are vital for safeguarding travertine surfaces by acting as a protective barrier against stains and moisture. There are two primary categories of sealers applied to travertine: penetrating sealers and topical sealers.

Pentrating sealers are specifically designed to seep into the stone’s pores, establishing a barrier that prevents liquid absorption while maintaining the stone's natural appearance and texture. This type of sealer is particularly effective for outdoor settings, as it allows for breathability while protecting against water and harmful substances. Given the unpredictable weather conditions in the UK, penetrating sealers are ideal for shielding against rain and humidity.

Conversely, topical sealers create a protective film on the stone's surface. These sealers can provide a glossy finish that enhances the beauty of travertine, making them a popular choice for indoor applications. However, topical sealers may degrade more rapidly and typically require more frequent reapplications, especially in high-traffic areas. A comprehensive understanding of the various types of sealers empowers homeowners to make informed decisions about their travertine flooring or surfaces.

Recognising the Importance of Removing Old Sealers

Removing outdated sealers is a crucial facet of travertine maintenance that should never be disregarded. Over time, sealers can deteriorate, resulting in a dull, discoloured, and unattractive appearance. The accumulation of dirt, grime, and other contaminants can exacerbate the problems caused by a failing sealer, culminating in a tired and worn-out look.

Moreover, neglecting to remove old sealers can trap moisture beneath the surface, creating an ideal breeding ground for mould and mildew. This not only poses health risks but can also lead to expensive repairs. By understanding the safest way to strip old sealers off travertine, homeowners can effectively rejuvenate their surfaces, restoring their natural beauty and prolonging the lifespan of the stone.

Regular maintenance, including the removal of aged sealers, is essential to prevent the buildup of contaminants and ensure that the travertine remains visually appealing and structurally sound. With the right care, travertine can continue to be a beautiful feature in any home, showcasing the charm of classic British architecture.

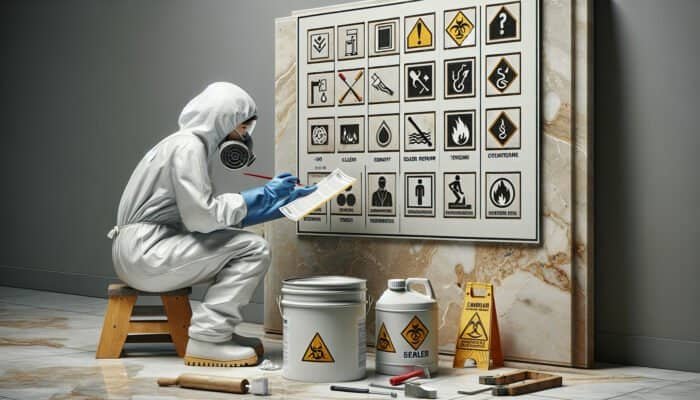

Essential Safety Protocols for Sealer Removal

Why Wearing Protective Gear is Crucial During Sealer Removal

When undertaking the task of stripping old sealers from travertine, prioritising safety is of the utmost importance. The chemicals found in sealer removers can pose significant risks, making it essential to don appropriate protective gear. Start by wearing gloves to safeguard your skin from potential chemical burns or irritations.

Goggles are equally essential, especially when working with liquids that may splash during application or removal. Protecting your eyes from harsh chemicals is vital, as accidental exposure can lead to severe irritation or injury. Additionally, wearing a mask is important to avoid inhaling harmful fumes, particularly in poorly ventilated spaces. Being adequately equipped will not only protect your health but also provide peace of mind throughout the project.

It's also advisable to wear old clothing or an apron, as chemicals can stain fabrics. This approach allows you to work without worrying about ruining your attire. Implementing these precautions will enhance both safety and efficiency during the sealer removal process.

How to Maintain Proper Ventilation During the Process

Ensuring proper ventilation is a vital safety measure when stripping old sealers from travertine. Many chemical removers release vapours that can be harmful if inhaled. Therefore, working in a well-ventilated environment is essential to limit the concentration of these fumes in the air.

Open windows and doors to create a cross-breeze that allows fresh air to circulate while using the chemicals. If possible, use fans to improve airflow, helping to disperse fumes from the workspace. In situations where outdoor ventilation is not an option, consider using an air purifier equipped with a HEPA filter to capture harmful particles and enhance air quality.

Additionally, it's wise to take regular breaks to step outside for fresh air, reducing exposure to any lingering vapours. Maintaining good ventilation not only promotes safety but also improves the overall effectiveness of the stripping process, ensuring that the chemicals work as intended without being hindered by vapour accumulation.

Practising Safe Handling of Chemicals

Safe handling of chemicals is paramount when stripping old sealers from travertine. Always read the manufacturer's instructions and safety data sheets for the products you intend to use. These documents provide crucial information regarding safe handling, potential hazards, and appropriate disposal methods.

When applying the sealer remover, use a designated container and tools that are compatible with chemicals to prevent any adverse reactions with incompatible materials. Ensure that your workspace is free from flammable items and that children or pets are kept at a safe distance.

Furthermore, it’s essential to comply with local regulations regarding the disposal of chemical products. Many regions have specific guidelines for disposing of hazardous materials, which may require taking them to a designated waste facility. By following safe practices and handling chemicals responsibly, you can protect yourself and the environment while effectively removing old sealers.

Choosing the Most Effective Sealer Remover for Travertine

Understanding the Different Types of Sealer Removers Available

Selecting the right sealer remover is a critical step in the process of stripping old sealers from travertine. There are two main categories of sealer removers: solvent-based and water-based. Each type provides distinct advantages and considerations, influenced by the nature of the sealant previously applied.

Solvent-based removers are often more potent and effective at breaking down heavy-duty sealers. They are particularly advantageous for penetrating sealers, which may resist removal. However, these products can emit strong fumes and pose health risks if not handled properly. Therefore, ensuring proper ventilation and wearing suitable protective gear is critical when working with these solutions.

On the other hand, water-based removers are generally milder and less toxic, making them a safer option for indoor use. They effectively remove topical sealers that may have developed a thick coating over time. Although they may take longer to work compared to solvent-based products, their ease of use and lower environmental impact make them appealing for many homeowners seeking a safer alternative.

Understanding the specific type of sealer used on your travertine will assist in selecting the most effective remover, ensuring a successful stripping process without risking damage to the stone.

Considering the Environmental Impact of Sealer Removers

In today's environmentally-conscious world, opting for eco-friendly sealer removers is beneficial for both personal health and the planet. Many traditional solvents contain harsh chemicals that can harm aquatic ecosystems and contribute to air pollution. By selecting biodegradable and non-toxic products, you can reduce your ecological footprint while effectively stripping old sealers from your travertine.

Look for sealer removers that are labelled as environmentally safe. These products are designed to decompose into less harmful substances, ensuring that any residues left after use do not negatively impact the environment. In the UK, numerous suppliers offer eco-friendly options, providing homeowners with confidence that they are safeguarding both their homes and the planet.

Additionally, using eco-friendly products often results in fewer harmful fumes, creating a safer and more pleasant working environment. By making informed decisions about the chemicals you employ, you contribute to a sustainable future while preserving the beauty of your travertine surfaces.

Assessing Compatibility with Travertine Before Usage

Ensuring compatibility between the chosen sealer remover and travertine is critical to avoid damaging this sensitive stone. Travertine is porous and can react adversely to harsh chemicals, potentially causing etching or discolouration. Therefore, it is vital to carefully review product labels and select removers specifically designed for natural stone surfaces.

Conducting a test on a small, inconspicuous area before full application can provide valuable insight into how the travertine will respond. This patch test allows you to determine whether the product causes any discolouration or damage, enabling you to make an informed choice before proceeding with the entire surface.

Additionally, consulting with professionals or reading reviews from other users can offer further insights into the effectiveness and safety of specific products. By ensuring that the remover you choose is compatible with travertine, you can confidently proceed with the stripping process while preserving the integrity and beauty of your stone.

Effective Techniques for Applying Sealer Remover

Employing appropriate application techniques is essential for achieving optimal results when stripping old sealers from travertine. Begin by thoroughly cleaning the surface to eliminate any loose dirt or debris, as this step significantly enhances the effectiveness of the sealer remover.

Once the surface is prepared, apply the sealer remover evenly, adhering to the product’s instructions regarding the recommended thickness and application method. For best results, use a brush or roller to ensure a consistent layer across the travertine, avoiding puddles that can lead to uneven stripping.

Allow the remover to dwell for the recommended time, as this contact duration is crucial for effectively breaking down the old sealer. Afterward, use a scrub brush or scraper to gently lift the softened sealer, being careful not to scratch the travertine surface. Finally, rinse the area thoroughly with clean water to eliminate any residue from the sealer remover, ensuring that the stone is clear and prepared for subsequent steps.

Maintaining patience and attention to detail during the application process will yield significant benefits, helping restore your travertine to its original beauty.

Step-by-Step Instructions for Effectively Stripping Travertine Sealers

Thoroughly Preparing the Surface for Sealer Removal

Before commencing the sealer removal process, it's essential to adequately prepare the travertine surface to ensure optimal results. Begin by sweeping or vacuuming the area to eliminate any loose dirt and debris. This initial cleaning step is vital, as any remaining particles can hinder the effectiveness of the sealer remover, potentially leading to an uneven application.

Next, wash the travertine using warm water mixed with a mild detergent to remove any oils or contaminants that may have accumulated over time. Avoid harsh chemicals that could harm the travertine. After washing, rinse the surface thoroughly with clean water to ensure that no detergent residue remains. Allow the surface to dry completely before applying the sealer remover, as moisture can dilute the effectiveness of the chemicals and obstruct the stripping process.

Once the travertine is dry, inspect the surface for any cracks or damage. Addressing these issues beforehand can prevent complications during the sealer removal process. By dedicating time to proper preparation, you lay the groundwork for a successful stripping procedure, ultimately preserving the integrity of your travertine.

Exercising Care When Applying the Sealer Remover

With the surface prepared, it’s time to apply the sealer remover. Start by meticulously reading the manufacturer’s instructions to comprehend the proper application method and safety precautions. Using a brush or roller, apply an even coat of the remover across the travertine surface, ensuring that all areas are uniformly covered.

Exercise caution not to apply the remover too thickly, as excessive amounts can result in pooling, which may damage the stone. Instead, aim for a moderate layer that will effectively penetrate the existing sealer without compromising the travertine beneath.

As you apply, pay close attention to the dwell time recommended by the manufacturer. This waiting period is crucial for allowing the remover to penetrate and dissolve the old sealer efficiently. Depending on the product, you may need to let it sit for anywhere from 15 minutes to several hours. After this period, check a small area to evaluate the remover's effectiveness. If the sealer has softened enough, you can move on to the next step.

Careful Removal of the Old Sealer

Once the sealer remover has had sufficient time to work, it’s time to lift the old sealer from the travertine. Begin by gently using a scrub brush or a plastic scraper to remove the softened sealer. Avoid metal scrapers, as they can scratch or damage the travertine. Instead, opt for tools specifically designed for delicate surfaces.

As you work, be meticulous in removing all remnants of the old sealer, ensuring that no residues are left behind that could interfere with the re-sealing process later. After extracting as much sealer as possible, rinse the area thoroughly with clean water to wash away any remaining chemicals and debris.

Following this, allow the travertine to dry completely. This step is crucial, as any moisture left on the surface can affect the adhesion of the new sealer that will be applied next. By carefully removing the old sealer and thoroughly cleaning the surface, you effectively prepare your travertine for the next phase of restoration.

Avoiding Common Mistakes During the Sealer Removal Process

The Dangers of Using Inappropriate Products

One of the most common missteps during the sealer removal process is using inappropriate products. Many homeowners may be tempted to resort to harsh chemicals or abrasive cleaners that can cause irreparable harm to the travertine surface. Such products can lead to lasting damage, including etching or discolouration, which may be difficult or even impossible to reverse.

To avoid this issue, it is crucial to select a sealer remover specifically formulated for natural stone surfaces. Always read labels and product descriptions to ensure compatibility with travertine. If uncertain, seek advice from professionals or consult suppliers who specialise in stone care for invaluable insights into the safest and most effective products for your travertine.

Moreover, avoid substituting household cleaners for traditional sealer removers. While they may seem harmless, they can contain ingredients that could harm the stone. Being mindful of the products you choose can prevent costly damage and promote a successful stripping process.

The Importance of Thorough Rinsing

After successfully removing the old sealers, it’s imperative to rinse the surface thoroughly. Inadequate rinsing can lead to residue buildup, potentially causing staining or damage to the travertine over time. Even small remnants of sealer remover left behind can negatively impact the performance of any new sealer applied later.

To ensure a comprehensive rinse, use copious amounts of clean water along with a soft cloth or mop to wipe down the surface. Rinsing multiple times may be beneficial to guarantee that all residues have been eliminated. Additionally, inspect the travertine post-rinsing to confirm that no residue remains. Dedication to this step will help preserve the beauty and integrity of your travertine.

Prioritising Safety Throughout the Stripping Process

Neglecting safety measures during the stripping process can lead to serious repercussions. Many homeowners underestimate the dangers associated with the chemicals used in sealer removers, which can result in accidents or health issues. Always prioritise safety by ensuring you wear appropriate protective gear, including gloves, goggles, and masks, as previously discussed.

Furthermore, it is essential to read and understand the safety data sheets for all products being used. These documents outline potential hazards and provide guidance for safe handling. Overlooking these precautions not only puts you at risk but also can lead to environmental harm. By taking safety seriously, you protect yourself while creating a safer working environment as you effectively restore your travertine surfaces.

Post-Sealer Stripping Care for Travertine Surfaces

Ensuring Complete Drying of the Surface

Once the old sealer has been removed and the travertine rinsed thoroughly, it is crucial to allow the surface to dry completely before applying a new sealer. Trapped moisture beneath a new sealer can lead to complications, including improper adhesion and potential damage to the stone.

To facilitate drying, ensure the area is well-ventilated. Open windows or use fans to enhance airflow, allowing moisture to evaporate more quickly. The drying time for travertine can fluctuate based on the humidity and temperature of the environment; however, it is advisable to wait at least 24 hours to ensure complete dryness.

A thorough check of the surface is also vital before proceeding. The travertine should feel completely dry to the touch, with no damp patches remaining. Taking this extra time to ensure the surface is arid will significantly enhance the efficacy of the new sealer, resulting in a durable and long-lasting finish.

Diligently Inspecting for Any Damage After Stripping

After the surface has dried, it’s time to closely examine the travertine for any damage that may have occurred during the stripping process. Thoroughly check the stone for signs of etching, scratches, or discolouration, as these issues must be addressed before applying a new sealer.

If any damage is found, consider consulting a professional who specialises in travertine restoration. They can provide recommendations on the best methods for repairing any imperfections. Promptly addressing these issues will help ensure that your travertine not only looks appealing but also remains structurally sound.

Additionally, use this opportunity to assess how well the travertine has cleaned up. If there are still areas that appear discoloured or stained after stripping, it may be worthwhile to invest time in further cleaning or consider a different sealer removal method. A thorough inspection is a critical step that lays the foundation for the successful re-sealing of your travertine.

Applying a New Sealer for Optimal Protection

With the old sealer removed and the surface thoroughly inspected, you are now ready to apply a new sealer. Choosing the right sealer is crucial for protecting the travertine while enhancing its natural beauty. Consider the specific requirements of your space—whether it’s in high-moisture areas or high-traffic zones—and select a sealer that meets those needs.

Follow the manufacturer’s application guidelines, ensuring that the surface is applied evenly. Use a brush or roller to cover all areas thoroughly, being careful not to overload the applicator to avoid drips. Depending on the type of sealer chosen, you may need to apply multiple coats to achieve the desired coverage. Ensure adequate drying time between applications, as specified in the product instructions.

After applying the new sealer, allow the travertine ample time to cure before returning it to regular use. This will ensure that the sealer bonds effectively and provides optimal protection against future stains and moisture.

Thoroughly Cleaning Residues Before Sealing

Following the stripping process and prior to applying a new sealer, it’s critical to ensure that any residues remaining from the stripping process are thoroughly cleaned off. Use a mild detergent mixed with warm water and a soft brush or cloth to gently wipe down the travertine surface.

This step is vital to prepare the stone for sealing. Residual substances can hinder the adhesion and performance of the new sealer, leading to potential issues down the line. Be diligent in your cleaning, rinsing the surface multiple times to ensure that all soap residues are removed.

After cleaning, allow the travertine to dry completely. Proper surface preparation will significantly contribute to the longevity and effectiveness of the new sealer, maintaining the beauty and integrity of your travertine for years to come.

Polishing Travertine for Enhanced Aesthetic Appeal

Once the new sealer has cured, consider polishing the travertine to restore its shine and smoothness. Polishing can accentuate the stone’s natural beauty, making it appear vibrant and fresh. Use a polishing compound specifically designed for natural stone and apply it according to the manufacturer’s instructions.

This step not only enhances the appearance of the travertine but also provides an additional layer of protection against stains and damage. Regular polishing can help maintain the stone’s lustre, making it easier to clean and keep looking its best.

Incorporating polishing into your maintenance routine can greatly elevate the overall aesthetic appeal of your travertine surfaces, ensuring they remain a stunning feature in your home for many years to come.

Frequently Asked Questions About Travertine and Its Sealers

What type of sealer is most suitable for travertine surfaces?

The optimal type of sealer for travertine is generally a penetrating sealer, which offers effective protection while allowing the stone to breathe. This characteristic is particularly important for outdoor applications.

How frequently should I strip and reseal my travertine?

It is generally advised to strip and reseal travertine every 1-3 years, depending on foot traffic and environmental conditions. Regular maintenance can significantly extend the lifespan of the surface.

Is it safe to use vinegar for cleaning travertine?

No, vinegar is acidic and can damage travertine. Instead, opt for a pH-neutral cleaner specifically formulated for natural stone to avoid etching.

How can I determine if my travertine sealer needs reapplication?

If water no longer beads on the surface or if stains penetrate quickly, it may be time to strip and reapply the sealer to maintain adequate protection.

Is using a power washer advisable on travertine surfaces?

Using a power washer on travertine is generally not recommended. The high-pressure water can damage the porous surface, leading to etching or cracking.

What is the recommended technique for applying sealer remover?

Apply sealer remover using a brush or roller for an even coat, following the manufacturer’s instructions regarding dwell time and application technique.

Can I use a scrub brush on travertine surfaces?

Yes, a soft scrub brush can be used to remove old sealer. However, avoid using abrasive brushes that may scratch the surface.

How long does it usually take for travertine to dry after sealer removal?

The drying time for travertine after sealer removal can vary, but it generally takes at least 24 hours for the surface to dry completely.

What should I do if I accidentally damage my travertine?

If you damage your travertine, it is advisable to consult a professional stone restoration specialist who can assess the damage and recommend suitable repair solutions.

What is the safest method for stripping old sealers off travertine?

The safest approach to removing old sealers from travertine involves using compatible, eco-friendly sealer removers, wearing protective gear, ensuring adequate ventilation, and closely following the manufacturer’s guidelines throughout the application process.

The Article What is the Safest Way to Strip Old Sealers Off Travertine first found on https://www.abbeyfloorcare.co.uk

The Article Safest Methods for Stripping Old Sealers from Travertine appeared first on https://fabritec.org

The Article Safest Methods to Remove Old Sealers from Travertine Was Found On https://limitsofstrategy.com